Don’t Let the Moon Delay Your Medals: The Race Director’s Guide to Lunar New Year

February 3, 2026

Summary: For Race Directors planning Spring events, the Lunar New Year is a critical supply chain disruption often overlooked. Discover how the shifting lunar calendar impacts manufacturing deadlines and use our 5-year “Danger Zone” guide to ensure your medals and shirts arrive before race day.

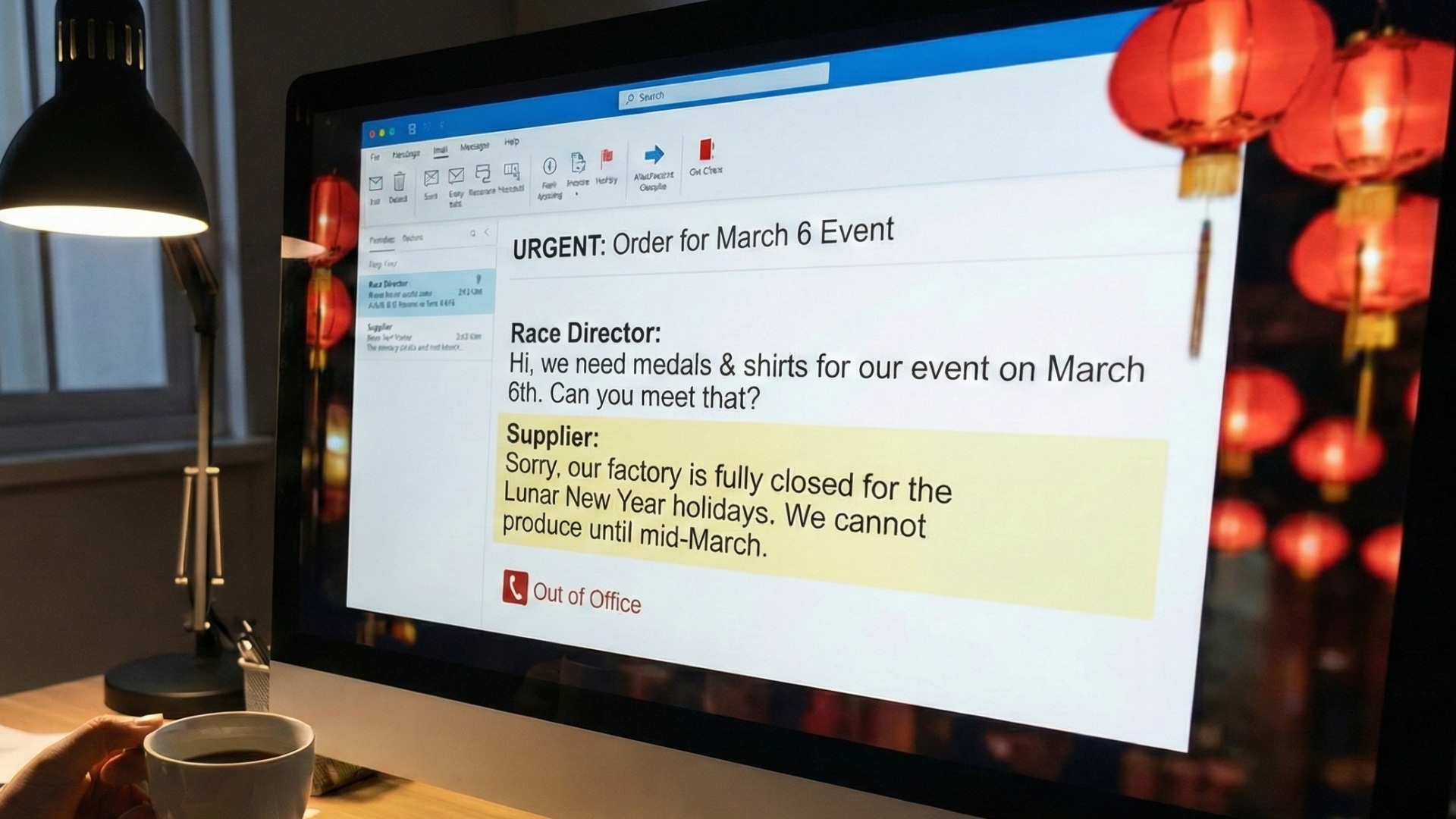

February 3, 2026 /ENDURANCE SPORTSWIRE/ – Imagine this: It’s late January. Your race is coming up in early March. Registration numbers are spiking, and you realize you need another 500 shirts and 1,000 medals. You email your supplier, ready to pay a rush fee, only to hear: “Sorry, we can’t produce anything until March 10th.”

Panic sets in. But why?

The reason isn’t lack of effort—it’s the Lunar New Year (LNY).

For Race Directors in the West, this holiday is often a blind spot in the production calendar. But given that the vast majority of race swag (medals, apparel, promotional items) is manufactured in Asia, understanding LNY is not just a cultural lesson—it’s a critical logistical necessity to ensure your gear arrives on time.

What Exactly is the Lunar New Year?

Unlike the Gregorian calendar (Solar calendar) used in the West, which is fixed at 365 or 366 days, the Lunar calendar is based on the cycles of the moon phases.

Because a lunar month is shorter than a solar month, a lunar year can be 12 months or sometimes 13 months (adding a “leap month” to catch up). This means the Lunar New Year doesn’t fall on the same day every year. It drifts, fluctuating by up to 30 days relative to the Gregorian calendar.

For example, in 2023, the Lunar New Year fell on January 22nd. However, in 2026, it lands on February 17th. That is a shift of nearly a full month (27 days), completely changing the production landscape from one year to the next.

For planning purposes, here is the LNY date schedule for the past 5 years and the next 5 years:

| Year | Lunar New Year Date | The “Danger Zone” for Production |

| 2021 | Feb 12 | Jan 20 – Mar 5 |

| 2022 | Feb 1 | Jan 10 – Feb 25 |

| 2023 | Jan 22 | Jan 1 – Feb 20 |

| 2024 | Feb 10 | Jan 20 – Mar 1 |

| 2025 | Jan 29 | Jan 10 – Feb 25 |

| 2026 | Feb 17 | Jan 25 – Mar 10 |

| 2027 | Feb 6 | Jan 15 – Mar 1 |

| 2028 | Jan 26 | Jan 5 – Feb 20 |

| 2029 | Feb 13 | Jan 20 – Mar 5 |

| 2030 | Feb 3 | Jan 10 – Feb 25 |

The “One Month” Shutdown: What Really Happens?

You might think, “It’s just a holiday, right? Like Christmas? Maybe they close for a few days?”

No. In the manufacturing world, LNY is a massive, month-long migration. Hundreds of millions of workers travel from industrial coastal cities back to their inland hometowns to visit family.

The typical timeline looks like this:

- 15 Days Before LNY: Production slows down. Workers start leaving early to beat the travel rush. Critically, logistics companies often stop picking up cargo one week before the holiday begins.

- LNY Week: Total shutdown. Nothing moves.

- 15 Days After LNY: The “Ramp Up.” Factories reopen, but not at 100%. Workers return slowly, and factories often have to hire and train new staff to replace those who didn’t return.

How This Affects Your Race Timeline

The impact depends entirely on when the holiday falls that year. Here are the two main scenarios:

Scenario A: Early LNY (Around Feb 1st)

- The Impact: January effectively only has two weeks of normal production. Factories are extremely busy rushing to finish pre-holiday orders.

- The Risk: If you place an order on Jan 5th hoping for a pre-holiday shipment, it’s extremely risky. Quality control can slip during the “mad dash” before the break.

- The Solution: Treat December as your ordering deadline.

Scenario B: Late LNY (Around Feb 10th – 17th)

- The Impact: You have a safe production window in January.

- The Risk: Factories won’t be fully operational until March 5th or later.

- The Trap: If you have a race in early or mid-March, you cannot rely on production in February. Even though the holiday starts mid-month, your order must be produced and shipped before the holiday begins. If it gets stuck at the factory when the lights go out, it stays there for 4 weeks.

Beyond the Factory: The Hidden Bottlenecks

Even if you find a factory willing to work late, two other factors can derail a tight schedule:

- Raw Materials: A sewing factory might be open, but the fabric mill or the zipper supplier might have closed a week earlier. Without materials, production halts.

- The “Logistics Jam”: Every importer in the world is trying to get goods on a ship or plane before the holiday. Ports become congested, and shipping prices skyrocket. Even if your shirts are finished, they might sit on a dock if not booked early.

The Golden Rule: Plan Ahead

At Magic Race Swag, we pride ourselves on punctuality. But we can’t fight the moon.

Our advice for any race held between February and April:

Finalize your designs and place your orders by mid-December. This guarantees your swag is produced with the highest quality and shipped before the Lunar New Year curtain falls.

Don’t let the calendar surprise you. Let’s plan early so you can focus on the race, not the shipping tracking number.

About Magic Race Swag

Magic Race Swag is the #1 Interactive Experience Partner for the endurance industry. We specialize in turning standard race gear from a sunk cost into a valuable viral marketing engine.

Using our proprietary “Magic Tech,” we transform everyday items into unforgettable experiences. Our innovation lineup includes Color-Changing Shirts that react to sunlight, Sweat-Activated Shirts that reveal hidden motivational messages during the run, and the industry-first Color-Changing Medals. We also provide high-engagement Glow in the Dark Shirts for night events and our reusable Color-Changing Cups for finish line celebrations.

To explore custom concepts for your 2026 event, visit www.magicraceswag.com